COGNEX Smart Vision In-Sight Overview

-

COGNEX Smart Vision In-Sight Overview

In-Sight 7000

Small, robust, and smart

The new In-Sight 7000 vision system leads perfect innovation in the machine vision industry. They are equipped with more powerful vision tools, auto-focusing, integrated lighting and optical options, high speed image capture, capability to control and activate various external lighting, and sufficient input/output capability to respond to all testing scenario. All products are provided in compact-sized, industrial IP 67 packages.

In-Sight Micro

Smaller, smarter, and more convenient

The In-sight Micro series is a super small sized system series, as small as 30mm x 30mm x 60mm. This super-small system with its own Power over Ethernet functionality is the optimal option where the space is limited. In-Sight Micro comes with a wide variety of performance grades and tool sets to respond to various types of machine vision requirements.

In-Sight 5000

Robust, stable, and superb

In-Sight 5000 is an innovative machine vision series, with more than 15 different models supporting high speed, high resolution, colors, IDs, line scanning, or stainless steel surfaces. All products come in robust IP 67 packages. In-Sight 5000 is suitable for the most harsh and demanding environmental conditions.

In-Sight 500

Suitable for manufacturing process inspection of the highest speed.

In-Sight 500 Vision System is packaged in robust IP65 houses for the fixed type vision system of higher performance. In-Sight 500 vision system is capable of collecting at a higher speed, along it to collect 500 frames of partial images. With the In-Sight programming Interfaces, the IN-Sight 500 provides a wide variety of tool sets and high-communication protocols

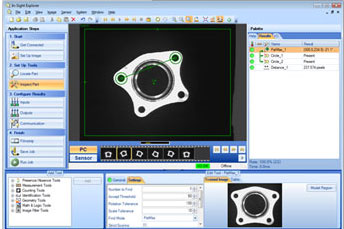

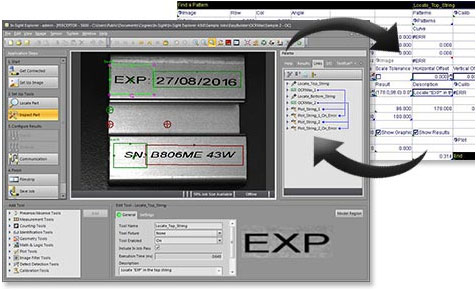

In-Sight Explorer

Powerful features, flexibility, and usability allowing optimized solution programming for suitable solutions for its own vision applications.

Affordable cost of ownership and speedy installation of the In-Sight Explorer Spreadsheet provides a flexible and efficient method to establish vision tools and process the data from them. Based on the vision tool of drag-and-drop features and menu-driven tool property sheets, the graphic pallet will make it a lot easier to compose the elements of your work. The In-Sight spread sheet provides highly advanced functions, options, and programs that can solve complicated application problems without writing a single line of code. The dependency of each tool can be expressed in a simple manner. Also, if you use the powerful CustomView Option, you can display the most important parameter of the process, which can be controlled easily by the operator. This will make the interaction with the operators much easier. You can also install the same CustomView on the VisionView operator interface panels.

With the Cognex Connect, In-Sight provides the most comprehensive and convenient communication links with the PLC, robots, factory network, and HMI devices.

In-Sight Vision Tool (with built-in cameras)

Powerful features, flexibility, and usability allowing optimized solution programming for suitable solutions for its own vision applications

Powerful location tool Pat Max In case the system fails to recognize the location of the parts consistently due to variation in the size and direction of the parts, it will significantly undermine the yield and reliability of the process. Such changes will include elements such as the following.

In-Sight Vision Tool (with built-in cameras)

Part locating tool (Including PatMax)

Tools including Inspect Edge and FFD (Flexible Flaw Detection) for detecting defects

Bead tests

Measurement tools

- Measures the distances between the pitchers, tolerances check, and edge searching,

Advantages of Cognex: - High precision measurement of dimensions of key parts without regard to changes in the orientation of the parts or the lighting in the room.